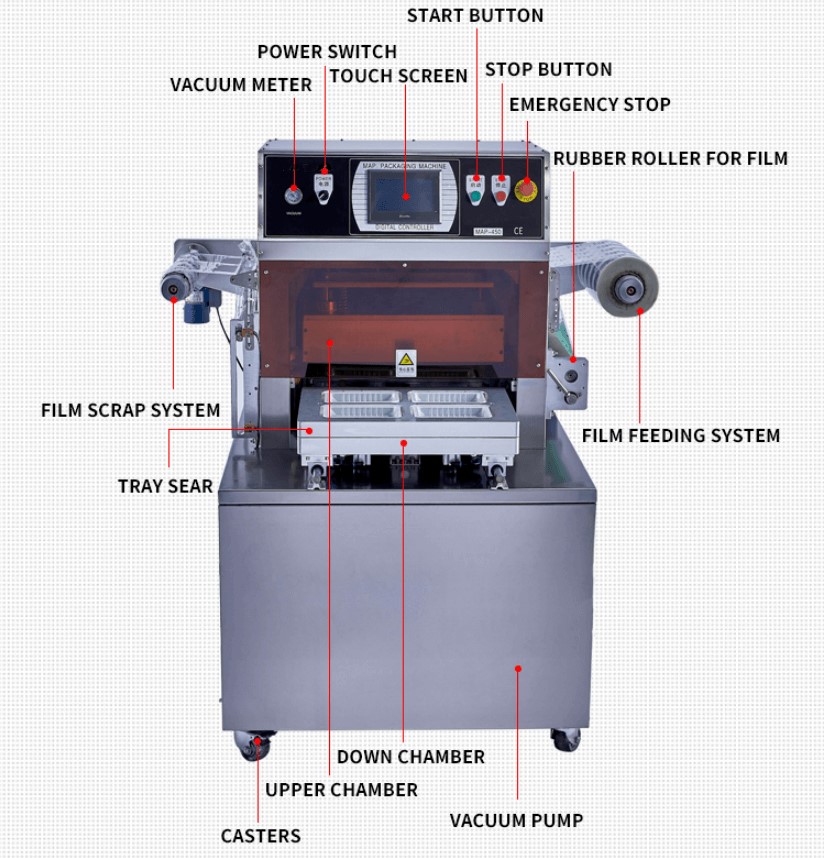

Advantage

* Indivdually built for your trays * Automatic film feeding, more sanitary

* Prelong shelf life of ready meal

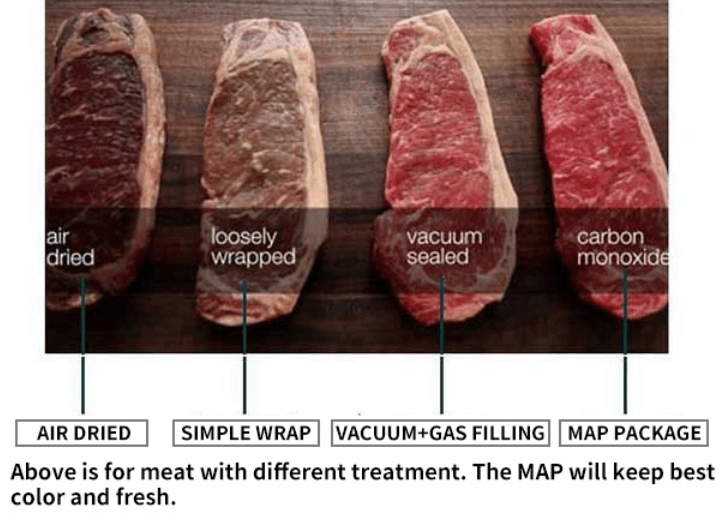

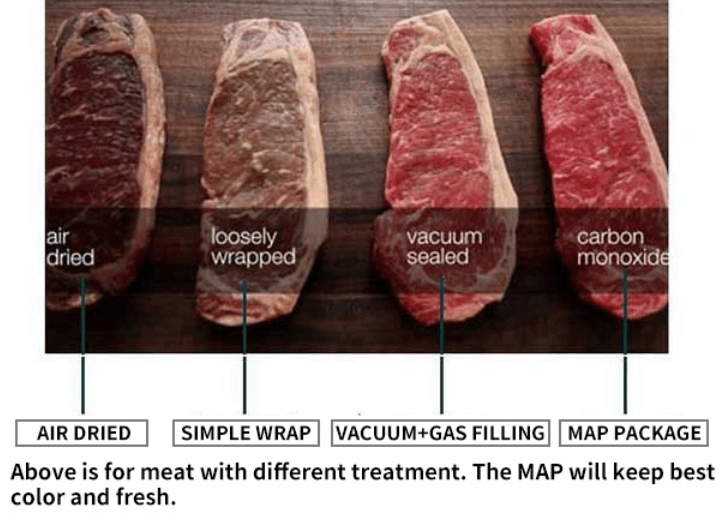

* Support modified atmosphere packaging

* Ratio of O2/N2/CO2 can be changed as per food

Advantage

* Indivdually built for your trays * Automatic film feeding, more sanitary

* Prelong shelf life of ready meal

* Support modified atmosphere packaging

* Ratio of O2/N2/CO2 can be changed as per food

* Prelong shelf life, remain fresh and taste of food

* Multi molds. Able to pack different tray size/shape.

* Customized mold as per client tray

* Easy for maintain and operate

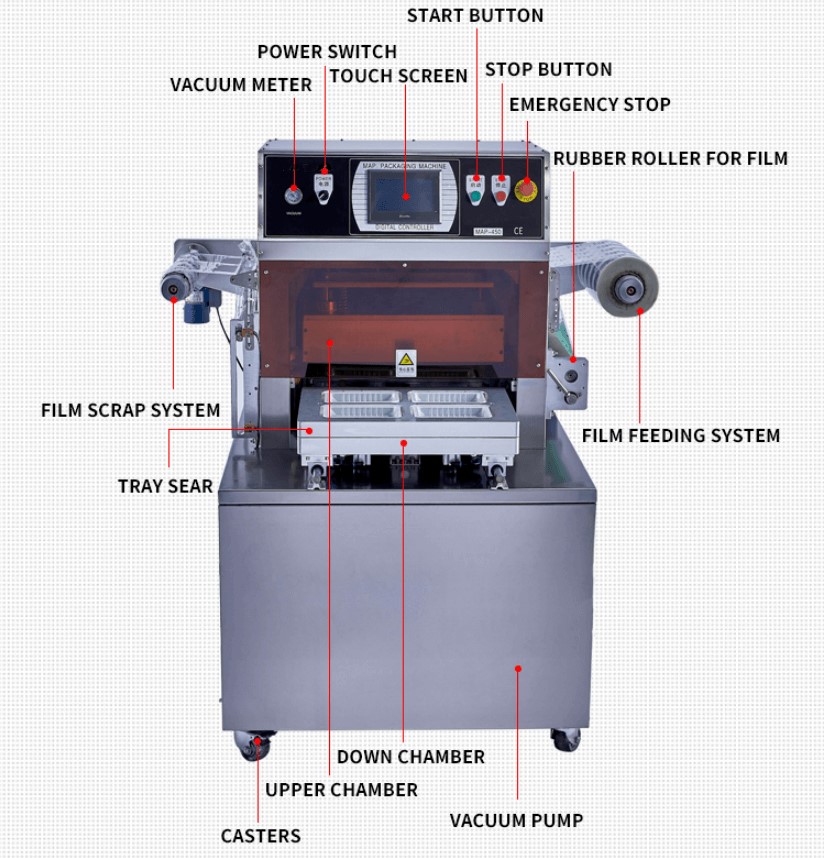

| Model |

MPA-450A |

MPA-450B |

| Voltage |

380V/50HZ/3phase or customized |

| Controller |

IDEC PLC + Weinview touch screen |

| Vacuum pump |

Chinese top brand ZD vacuum pump 63m3/h from German |

| Vacuum degree |

Maxi 0.1Mba |

| Material |

Mainly food grade 304SS |

| Tooling |

Include 1 tooling for one tray design. It is customized |

| Packing capacity |

About 3 cycles per minute |

| Overall size |

1350*1050*1650mm |

| Weight |

About 450KG |

| Gas source pressure |

0.2-0.3Mpa |

| Power consumption |

About 5KW |

| Certificate |

CE |

| Guarantee |

1 year |

| Language |

English/Chinese/Spain for option |

| Air compressor |

Not include in the price. The air pressure shall be about 0.6-0.8Mpa |

| Gas mixer |

Include one inside the machine |

Exclude |

| Function |

Vacuum, O2/N2/CO2 mix and fill, seal |

Vacuum, nitrogen fill, seal |

* Client can change gases ratio on touch screen as need.

* Above price do not include air compressor. It cost additionally

* We can customize wider/deeper chamber, with extra cost. if client has big or deep tray. Tray depth can be maxi 120mm.

* Voltage can be customized as required.

* Above price include one mold. Extra mold cost additionally. The machine support maxi 3 molds. Each tray size/shape require one mold.

* If client order more than 3pcs, there will be discount.

1. Suitable item

1. Suitable item. Food item like ready meal, meat, fish, sausage, cheese, fruit, vegetables, tofu, salad, sandwich, pizza, cooked food etc.

2. Tray size. Machines are customized accordingly to client tray size/shape. Above is just for reference.

3. Package type. Our machine can support tray+film. Opening aid corner is optional, with extra 150USD.

4. Package material. Trays made from PP / PET/ Aluminium foil.

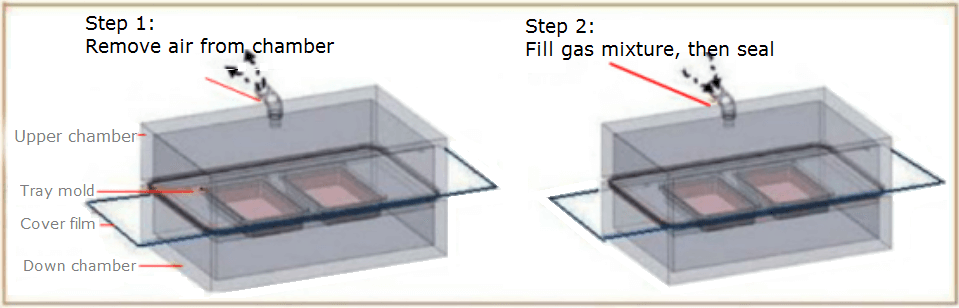

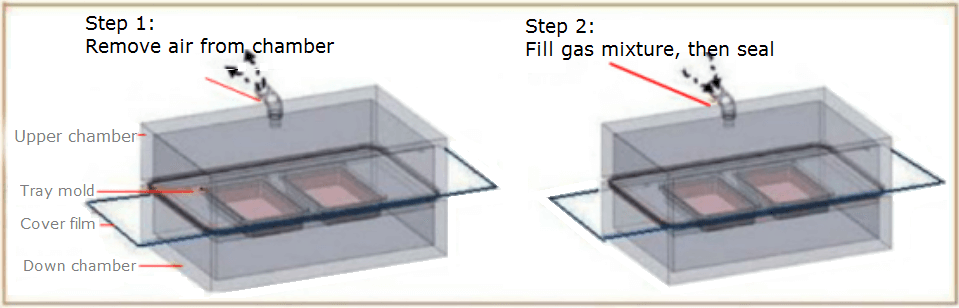

How the machine work for MAP?

The machine will remove air from tray, then fill modified gas into tray, and seal cover film. Whole process happens in a closed chamber.

Oxygen gas (O2). It keep fresh cell sleep but still alive.

How the machine work for MAP?

The machine will remove air from tray, then fill modified gas into tray, and seal cover film. Whole process happens in a closed chamber.

Oxygen gas (O2). It keep fresh cell sleep but still alive.

Carbon Dioxide gas(CO2). Inhibit the growth of aerobic bacteria.

Nitrogen gas (N2). Does not have special function. Nitrogen gas fill after vacuum, it protect good tray shape under atmospheric pressure.

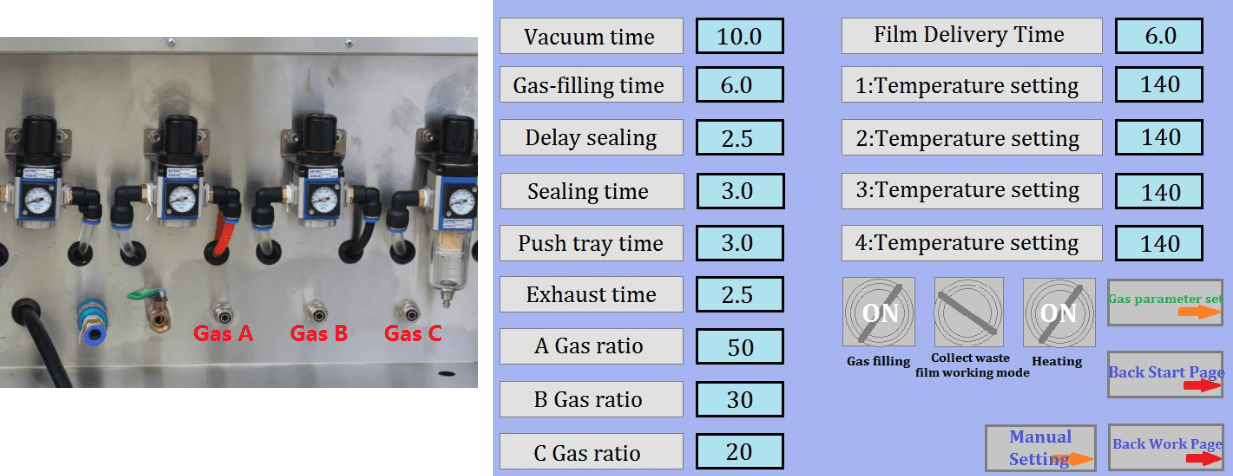

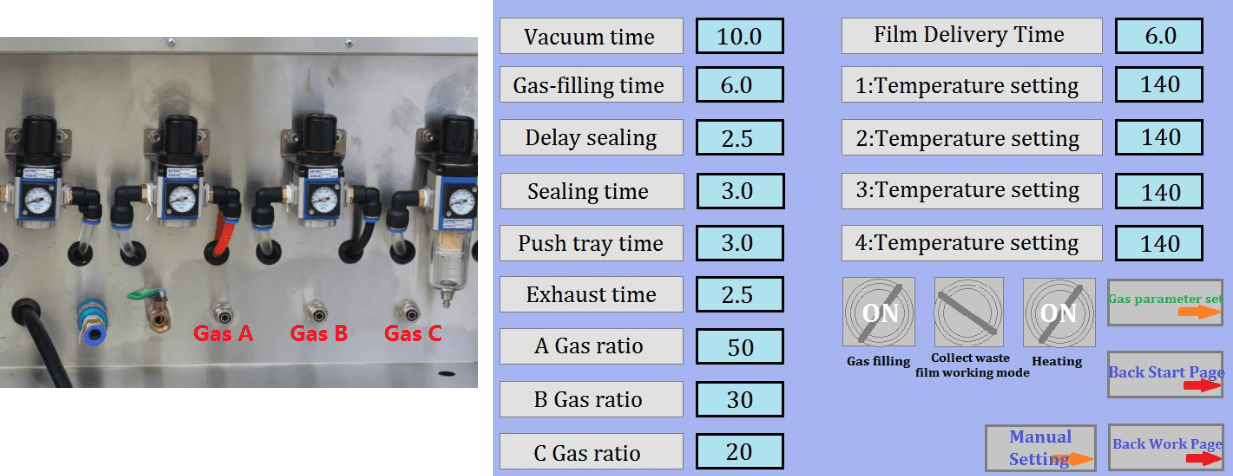

How to set touch screen

* We leave different holes for gases on tray sealer. Please connect them with gas source directly. Inflow gas pressure shall be 0.2-0.3Mpa.

* User can adjust gases ratio on touch screen.

* The gas mixer will mix gases and store them in another cylinder inside machine.

* The machine will automatically fill gas once inside gas less than a certain level.

* The touch screen will alarm for insufficient gas source inflow.

* Time for vacuum/gas fill/seal can be adjusted also. If want to close some function, just set the time "0".

How to set touch screen

* We leave different holes for gases on tray sealer. Please connect them with gas source directly. Inflow gas pressure shall be 0.2-0.3Mpa.

* User can adjust gases ratio on touch screen.

* The gas mixer will mix gases and store them in another cylinder inside machine.

* The machine will automatically fill gas once inside gas less than a certain level.

* The touch screen will alarm for insufficient gas source inflow.

* Time for vacuum/gas fill/seal can be adjusted also. If want to close some function, just set the time "0".

TAG:vacuum sealer with nitrogen gas flush map packaging machine for sale modified atmosphere packaging equipment nitrogen bag sealer vacuum nitrogen flushing sealing machine map sealer vacuum nitrogen sealer machines map vacuum sealer nitrogen gas flushing machine vacuum nitrogen sealing machine